Getting the Most from Your Converters with A Process You Can Trust: Understand the Importance of Weights

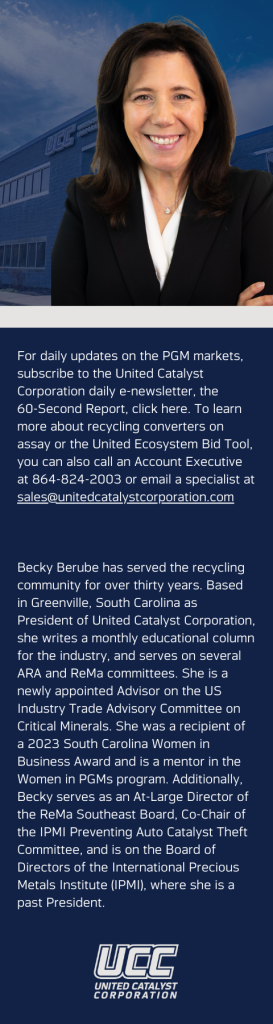

UCC Article Archive – February 13th, 2018 – Becky Berube

In converter recycling, the best recyclers know their numbers and partner with companies that educate. We encourage our customers to sell converters on assay, the verified analysis of the precious metal contained in the converters less the customary recycling costs. You want to use a scientific method because it is reliable and can be validated. By selling on the assay method and understanding key metrics, it is less likely that you will leave money on the table.

In the first article of this series, Getting the Most from Your Converters with A Process You Can Trust, we emphasized Know Your Numbers. We strongly advise our customers to know their count before they sell. Train a key person to count and inspect the converters before they are packaged up. Teach him or her the difference between the ceramic and metallic (foil/wire) converters. Without an accurate ceramic, metallic, empty, and DPF count it is impossible to know key bottom-line metrics like a true price per unit, price per pound, and average weight per unit. Like with selling whole units, these are areas that can contribute to misleading information and lost revenue.

In this article, we want to discuss why it is necessary to your bottom line to Understand the Importance of Weights. Next to knowing your unit count, the second most important aspect of selling converters is understanding the importance of weights.

If you’re missing weight, you’re missing money.

When you sell converters by the piece, you are at the mercy of the grade and the count being accurate and the price being fair. A slight of hand in any of these areas creates lost revenue. When you sell converters by the assay method, the same is true of the count, weight, and price. If you are going to get paid on the intrinsic value of the precious metal inside the converter, you want credit for everything.

If you want to know how much money you are really making every time you sell, you must learn your true price per unit, price per pound, and average weight per unit. For those three metrics to be accurate, the burden is on you to know your count and weights and hold the converter recycling company that recycles for you accountable.

Track your shipping and arrival weight. If you want a good ending result, i.e. maximum value, you need to agree on a beginning weight. When you receive a delivery confirmation notice from the company processing your converters make sure that the weight you shipped is very close to the weight that arrived. If you don’t have a scale, you can estimate your shipment by using 10 lbs. per converter. If the discrepancy is more than a few pounds find out why.

Work with companies that mass balance. Mass balance means that all weights in and all weights out are measured and accounted for with a small tolerance for loss. Our tolerance is one-half of one percent (0.5%). We weigh and photograph all incoming skids and provide that to you the recycler. This is the beginning weight that we agree upon with you. Throughout the process of de-canning, milling, sampling, and assaying everything is weighed: catalyst, dust, moisture, scrap steel, gaylord boxes, pallets, trash or inert material. Inert material and trash includes things like insulation, batting, and screens that surround the ceramic catalyst biscuit or substrate. If the weights in and the weights out do not balance, the material cannot ship to the refiner. For your protection, and ours, we expect the same process at the refiner. Our job is to ensure that all precious metal contained in the converters gets paid for.

Know your average weight per converter and price per pound. For a very long time, the average converter weighed 10 lbs. in the can and contained 2.2 pounds of ceramic catalyst. That’s approximately 20% catalyst to 80% steel. With car manufacturers demanding greater efficiency using less precious metal, we are seeing the average catalyst weight per unit trending downward to 1.8 or 1.9 pounds per unit. Recently, the average price per pound of recycled catalyst is yielding between $30 – $40 per pound. A discrepancy of even .3 pounds per unit could be costing you more than $10 a unit at $35 per pound (.3 x $35 = $10.50). Multiply that by the number of converters you are recycling, and the loss can be staggering.

Watch your trash and moisture. On the assay report that you receive, you should be able to see a weight reconciliation. The gross weight reported will typically be the catalyst and dust from de-canning without the packaging and steel. The net weight (wet) should be the weight of the catalyst less any trash or inert material as outlined earlier. The net weight (dry), or settlement weight, will be the weight of the catalyst less any moisture determined. Normally trash and moisture will run between 1 – 3 percent each of the gross weight and the net weight (wet) respectively unless there are extenuating circumstances like exposure to moisture. The catalyst substrate is porous and very susceptible to moisture.

The bottom line for successful recyclers who make the most money from their converter recycling program, is becoming educated and tracking the data and the money to insure against loss.