United Catalyst Corporation is a North American-based processor of scrap catalytic converters that offer global refining services. Getting you the most from your converters with a process you can trust. We feel that an educated customer is our best customer. We know this industry can be hard to navigate, but we have some expert tips to help you through the process of converter recycling.

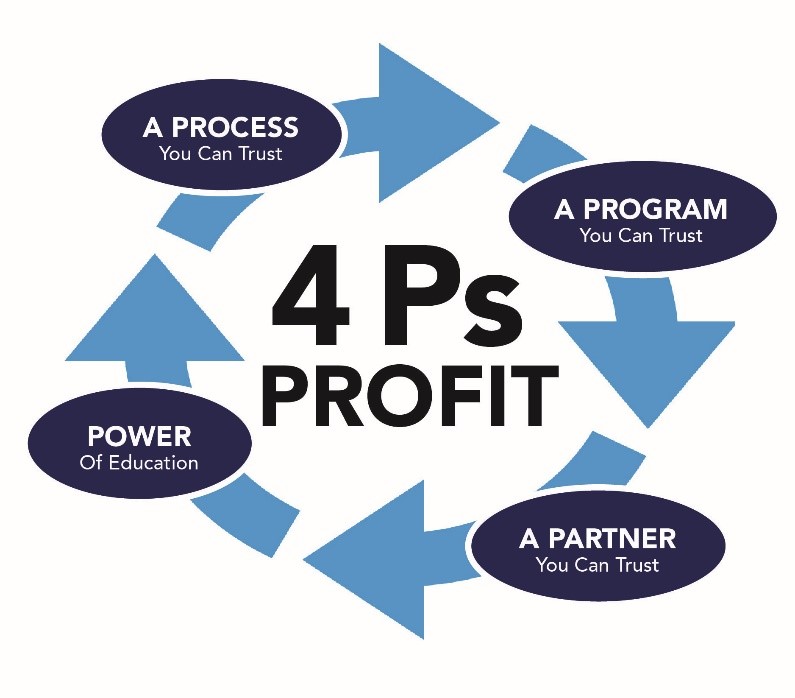

#1 Tip: Always follow The Four P’s of converter recycling profitability. You need a process, a program, and a partner you can trust. You also need to learn the power of Education.

#2 Tip: A Process You Can Trust – You can sell on assay instead of selling by the piece. You will need to be paid on a sample and assay that are official, accurate, and verifiable.

#3 Tip: A Program You Can Trust – You need to get money when you need it to run your business. Getting you the most money from your converters should not mean you have to wait three months to get paid or until you have a truckload. With most processors, you have payment choices.

#4 Tip: A Partner You Can Trust – Selling on assay or recovery helps eliminate grading scams and two-for-one sales because there is a test result that can be considered the basis for the sale. However, even with this method, nothing is guaranteed. Working with a partner you can trust cannot be overstated.

# 5 Tip: The Power of Education – We take a complex process and try to make it understandable and easy to use. You will increase your profits once you learn about your converters and your yard profile. No one will ever be able to take advantage of you again.

#6 Tip: Focus on the Numbers – We strongly advise our customers to know their count before selling. If you do not have an accurate unit count, you will not know your actual average.

#6 Tip: Focus on the Numbers – We strongly advise our customers to know their count before selling. If you do not have an accurate unit count, you will not know your actual average.

#7 Tip: Understand the Importance of Weights – Next to knowing your unit count, weights are the second most important piece of information. Be sure your processor is mass balancing all weights IN and OUT of their facility. If you are missing weight, you are missing money.

#8 Tip: Making Sense of the Assay Report and Final Invoice – Both can look like mumbo-jumbo, but when you understand what should be on them, you are less likely to fall prey to any unethical practices and leave money on the table.

#9 Tip: One Way. Assay. – Assay-based selling with a process, a program, and a partner you can trust (and verify) is the only way to maximize the money you get for your cats with any certainty. There is more than one good way to do most things in life. This is not true with converter recycling.

#10 Tip: Play the Long Game – Keep selling into the market on assay. Do not take unnecessary risks. Play the long game.

#11 Tip: Increase Your Averages – By switching to Assay, your average cat sale should be up anywhere from 5-45%, depending on how your buyer was treating you.

#12 Tip: Be Meticulous – Be meticulous about safeguarding your converters: locks, video, counts, personnel. Even if it takes a significant amount of time and money, do whatever it takes. The primary responsibility lies with you.

#13 Tip: Never tell your buyer, You Know Where They Are – If you are selling by the piece, never say to the converter company, “you know where they are.” This is a license to steal.

#14 Tip: Mark Your Cats – Another way to safeguard against theft is knowing your count and secretly marking your cats. If your cat count is consistently short when you sell, start marking them in an unknown way. Pick a color each week or month and spray inside the cat. If someone takes your converter and tries to come back and sell it to you, you have got them.

#15 Tip: Put Your Halves Aside – If you are selling by the piece, never let the company put the halves on the truck until you inspect them. If a converter is worth $300 and it’s three-quarters full, why would you take half price when the guy sells it as a full?

#15 Tip: Put Your Halves Aside – If you are selling by the piece, never let the company put the halves on the truck until you inspect them. If a converter is worth $300 and it’s three-quarters full, why would you take half price when the guy sells it as a full?

#16 Tip: Do Business with Good People – Good people need to do business with good people. Screen your clients and customers. Know your customer (KYC) is a legal requirement to comply with Anti-Money Laundering laws (AML). Protect yourself and your business.

#17 Tip: Become an Educated Customer – The best recyclers know their numbers in converter recycling and partner with companies that educate.

#18 Tip: Audit your program – Become a data junkie. Learn all the key metrics to avoid misleading data, like your average converter price, and track actual sales. As you gain data points, you will be amazed at how easy it is to get misled.

#19 Tip: Switch to Assay – There is only one way to recycle a scrap catalytic converter. It must be de-canned, milled, sampled, assayed, smelted, and refined.

#20 Tip: Get All the Money for Your Converters – How much money do you want from your converters? Your answer should be all of it. How do you get all the money from your converters? Process and sell them on assay.

If you have questions about this article or any issue pertaining to catalytic converter recycling, our team is here to assist you. Recycling converters on assay is a journey. We hope you will rely on us at United Catalyst as your guide. To subscribe to our daily e-newsletter or get Platinum Group Metal prices texted twice daily to your phone, TEXT Daily to 864-834-2003. You can also call us or email us at [email protected].

Selling on assay with refining terms is the best way to recycle scrap catalytic converters. In fact, it is the only way to recycle a converter. It happens once it leaves your facility whether you sell it this way or not. The trick to selling on assay is fourfold: Knowing the actual count including halves so that you can know your true average. Mass balancing all weights including shipping materials, scrap, catalyst, and dust. Scientifically accurate sampling collection to produce the sample of record from the refiner or a third-party lab. Verified assay results from the end refiner or third-party lab. Make sure you get paid on the “official assay of record” and make sure the assay results can be verified by a third party. Without one of these four aspects being true and accurate, you are sure to be leaving money on the table even when selling on assay, never mind when selling by the piece or on auction or with an app.

Selling on assay with refining terms is the best way to recycle scrap catalytic converters. In fact, it is the only way to recycle a converter. It happens once it leaves your facility whether you sell it this way or not. The trick to selling on assay is fourfold: Knowing the actual count including halves so that you can know your true average. Mass balancing all weights including shipping materials, scrap, catalyst, and dust. Scientifically accurate sampling collection to produce the sample of record from the refiner or a third-party lab. Verified assay results from the end refiner or third-party lab. Make sure you get paid on the “official assay of record” and make sure the assay results can be verified by a third party. Without one of these four aspects being true and accurate, you are sure to be leaving money on the table even when selling on assay, never mind when selling by the piece or on auction or with an app.

The drivers that visit the victory lane often know the car and equipment need to be exhaustively prepared. The driver knows they must be physically and mentally focused on enduring the challenges of racing. If the level of preparation is off by even a tiny percentage, the desired results will not be there. Race drivers watch videos, review data, practice on simulators, and drive the track mentally over and over. That is just part of preparing the driver.

The drivers that visit the victory lane often know the car and equipment need to be exhaustively prepared. The driver knows they must be physically and mentally focused on enduring the challenges of racing. If the level of preparation is off by even a tiny percentage, the desired results will not be there. Race drivers watch videos, review data, practice on simulators, and drive the track mentally over and over. That is just part of preparing the driver.

With more precious metals being used in converters and an average vehicle age of 20 at the time of scrappage, the supply of recycled PGMs especially Pd is expected to increase from 5 million ounces (MOZ) to 7 MOZ. by its peak in 2031-2032. As mobility trends toward fuel cell electric which uses more platinum in the storage of hydrogen energy, it is the long-term demand for palladium that is in question. If zero emission mandates are adopted to allow for only fully electric vehicles, plug-in hybrids (PHEVs) and hybrid electric vehicles (HEVs) will be eliminated along with ICE vehicles. Palladium demand will be seriously hampered. Consultant, Matt Watson, of Precious Metals Commodity Management, LLC, suggests that “Palladium will push from structural deficit to structural surplus without new demand source(s). It is not a question of if, it is a question of when.”

With more precious metals being used in converters and an average vehicle age of 20 at the time of scrappage, the supply of recycled PGMs especially Pd is expected to increase from 5 million ounces (MOZ) to 7 MOZ. by its peak in 2031-2032. As mobility trends toward fuel cell electric which uses more platinum in the storage of hydrogen energy, it is the long-term demand for palladium that is in question. If zero emission mandates are adopted to allow for only fully electric vehicles, plug-in hybrids (PHEVs) and hybrid electric vehicles (HEVs) will be eliminated along with ICE vehicles. Palladium demand will be seriously hampered. Consultant, Matt Watson, of Precious Metals Commodity Management, LLC, suggests that “Palladium will push from structural deficit to structural surplus without new demand source(s). It is not a question of if, it is a question of when.”

Selling by auction or collective bid: In recent years, many recyclers have found some peace of mind, and increased profits, in selling through an auction or bidding process. The theory is that the sale goes to the highest bidder, and you receive the “best” price. The downside to this method is that the buyer will most likely turn those converters around and sell them on recovery or assay which means you most likely left money or margin on the table.

Selling by auction or collective bid: In recent years, many recyclers have found some peace of mind, and increased profits, in selling through an auction or bidding process. The theory is that the sale goes to the highest bidder, and you receive the “best” price. The downside to this method is that the buyer will most likely turn those converters around and sell them on recovery or assay which means you most likely left money or margin on the table.

#15 Tip: Put Your Halves Aside – If you are selling by the piece, never let the company put the halves on the truck until you inspect them. If a converter is worth $300 and it’s three-quarters full, why would you take half price when the guy sells it as a full?

#15 Tip: Put Your Halves Aside – If you are selling by the piece, never let the company put the halves on the truck until you inspect them. If a converter is worth $300 and it’s three-quarters full, why would you take half price when the guy sells it as a full?

In an industry that has historically been rife with smoke and mirrors, as recyclers looking to get the most from your converters, you need a Process you can trust, a Program you can trust, and a Partner you can trust. You see, you can do everything right. You can sell on assay instead of selling by the piece. You can have excellent terms and pricing. But if you do not have a reputable partner that you can trust, you could still lose. President Ronald Reagan, on multiple occasions, used the Russian proverb, Trust but verify, in the context of nuclear disarmament. The same holds true in our part of the recycling industry. Selling scrap catalytic converters has always been a risky business. Taking a price on something where the value is unknown screams “seller beware.” Selling on assay or recovery helps eliminate that problem because there is a test result that can be considered the basis for the sale. However, even with this method, several things can still go wrong for the recycler: settling on an inaccurate or manipulated sample and/or assay result; losing weight during processing and refining; having too much trash and/or moisture; paying exorbitant recycling costs, and selling metal that is too heavily discounted. For all these reasons, the importance of working with a Partner you can trust cannot be overstated. The bottom line is that you need to be paid on a sample and assay that are official, accurate, and verifiable.

In an industry that has historically been rife with smoke and mirrors, as recyclers looking to get the most from your converters, you need a Process you can trust, a Program you can trust, and a Partner you can trust. You see, you can do everything right. You can sell on assay instead of selling by the piece. You can have excellent terms and pricing. But if you do not have a reputable partner that you can trust, you could still lose. President Ronald Reagan, on multiple occasions, used the Russian proverb, Trust but verify, in the context of nuclear disarmament. The same holds true in our part of the recycling industry. Selling scrap catalytic converters has always been a risky business. Taking a price on something where the value is unknown screams “seller beware.” Selling on assay or recovery helps eliminate that problem because there is a test result that can be considered the basis for the sale. However, even with this method, several things can still go wrong for the recycler: settling on an inaccurate or manipulated sample and/or assay result; losing weight during processing and refining; having too much trash and/or moisture; paying exorbitant recycling costs, and selling metal that is too heavily discounted. For all these reasons, the importance of working with a Partner you can trust cannot be overstated. The bottom line is that you need to be paid on a sample and assay that are official, accurate, and verifiable.